At Nimatex

As an important step for the sustainable fashion industry, eco friendly regenerated yarns are produced from recycled fibers, ensuring an environmental friendly production process by reducing the consumption of natural resources.

Open end machines use these recycled fibers to produce yarns of various colors and thickness, resulting in a high quality and variety of products. This trend is growing in the fashion industry and can be used in the production of many different clothing items and accessories.

The use of eco-friendly yarns is essential for a more sustainable and environmental friendly fashion industry and therefore regenerated yarns produced with the use of recycled fibers provide an important step for the fashion industry and a positive impact for the environment.

Regenerated Yarn

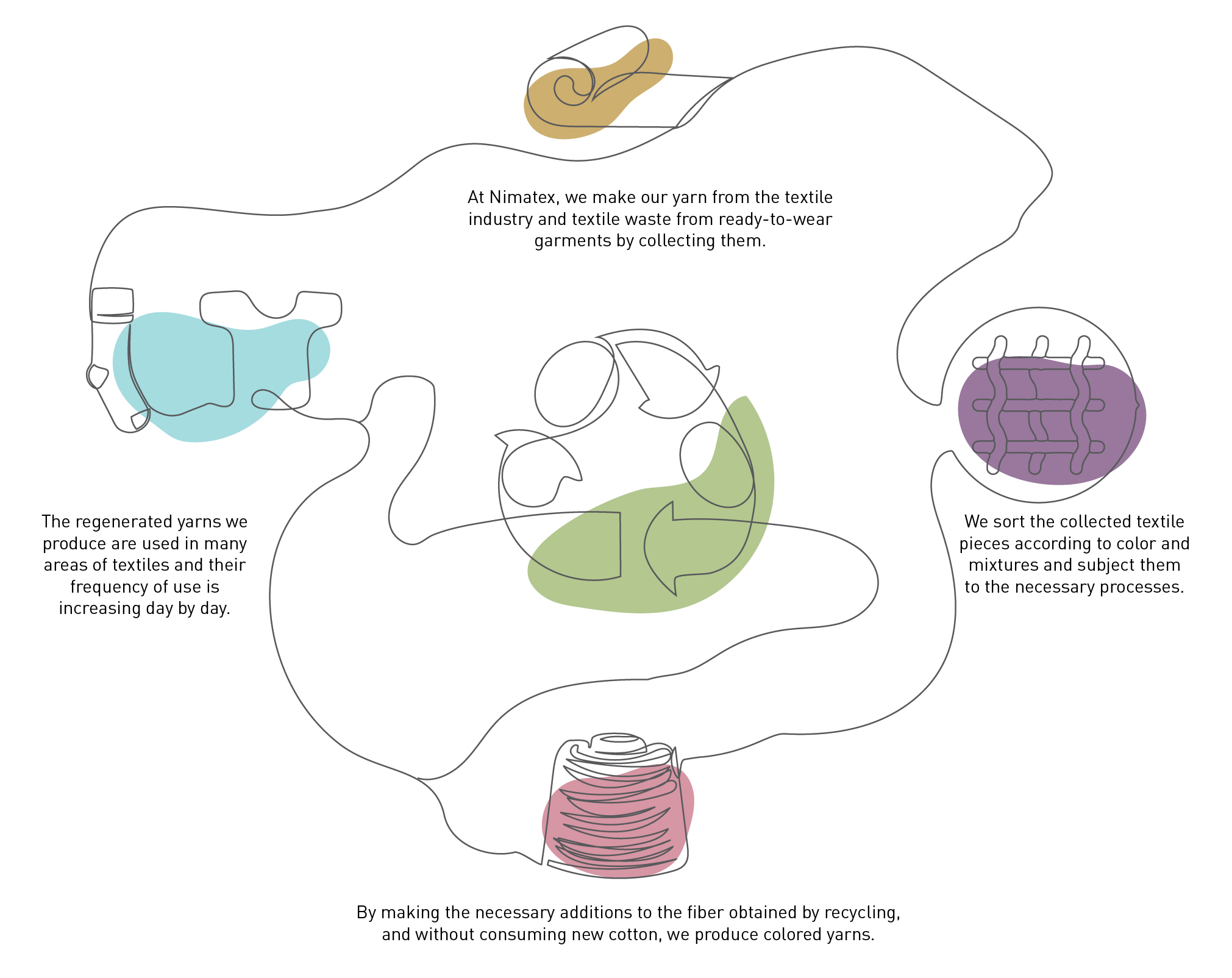

Thanks to the mechanical recycling method used for the recycling of textile wastes, wastes containing fibers such as cotton, viscose and polyester such as viscose, polyester trimmings are collected. These wastes are first sorted according to their color and raw material content and cut into small pieces. Afterwards, they are turned into fibers in opening machines called shifanoz, which are covered with fiber opening wires.

Fibers obtained from textile wastes are transformed by using open end spinning system and mixing with carrier fibers such as viscose, polyester, acrylic, which give strength to the yarn and enable the fibers to be transported, due to the lack of homogeneous raw material type and high proportion of short fibers. The yarns obtained in this way are referred to as “regenerated / regenerated yarn” or “recycled yarn” in the sector.

For regenerated yarn production, it is important that textile wastes are selected and collected on site and carefully separated according to their color and raw material content. After being turned into fibers, it is of great importance to mix them with original carrier fibers in appropriate proportions and properties according to their physical properties and to ensure standard yarn production at appropriate machine settings. Thanks to the production standardization and quality control system established in our enterprise, regenerated yarn with environmental friendly, recycling and ecology certificates is produced with quality characteristics that can compete with yarns produced from original fibers.

With this method, textile wastes are brought into the economy without harming the environment. Environmental benefits such as protection of agricultural lands, reduction of energy consumption, reduction of chemical processes and harmful effects are provided. Thanks to the use of recycled yarn, recycling of textile wastes, which is considered economically zero value, is encouraged and colored yarns containing cotton are obtained without using soil, tractor, water, chemicals. As a result, regenerated yarn production is a beneficial process for both the environment and the economy. When applied correctly, these yarns are easy to produce and cost-effetcive, making them a reliable alternative for many applications in the textile industry.